Spring 2016 3D SMD: Z-Axis Beam

By Henry Nguyen (Electronics and Control)

Table of Contents

Introduction

When running our accuracy tests, I found that the current beam on our Z-Axis would wobble. After carefully observing the wobbling, I found that this will be a major problem when we needed to assemble a PCB with surface mount components. The wobbling will cause our machine to be very inaccurate and may cause us to fail our machine.

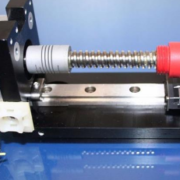

Old Beam

Figure 1. Old Beam

Not only was our old beam wobbling because the holes where the 4mm rod went through were slightly larger than 4mm. This will cause the beam to lean forward due to the weight of our A-axis stepper motor. Now that the beam is being tilt forward, our Z-Axis stepper motor will sometime stall out because of the friction against the 4mm rod and the thread beam.

New Beam

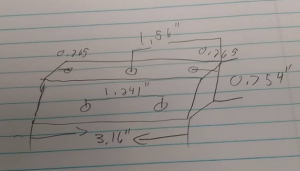

Figure 2. New Beam Measurements

For our new beam, I decided to make it approximately 0.754 inches. This meant that our beam will be longer than our older beam. I believed by extending the length, we will be able to prevent the wobbling caused by the two rods. The middle hole shown in the figure above will be tapped for our thread screw. The two holes in the middle is to attached our A-Axis stepper motor bracket.

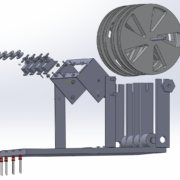

Figure 3: Z-Axis Beam Manufactured.

I was able to get Z-Axis beam manufactured. I found that after installing this bracket, we were able to solve the problem of our Z-Axis stepper motor stalling due to the proper size hole that the rod is now able to go through perfectly.

Figure 4. Lubricant

It was also important to apply some CRC Heavy Duty Silicone lubricant onto the beam and the thread screw to allow smooth vertical movement of our new beam. The following link is a video of our new beam in action.

Conclusion

It was very important to manufacture a new beam for our Z-Axis. Before we would have a lot of error caused by the Makeblock beam that came with our thread drive kit. The old beam would wobble a lot which is a major problem when we are trying to be as accurate as possible. Other times, the poorly manufactured beam would also cause our z-axis stepper motor to stall because it did not move up and down smoothly. By manufacturing this new beam we are able to increase our accuracy of our machine.