Spring 2016: 3DoT David Simulation and New Design Parts

BY: Andrew Saprid ( Manufacturing Engineer)

Introduction:

Since the first prototype made in solidworks was difficult to 3D print, the parts had to be redesigned. They have to be as flat as possible to make it easier for the 3D print the parts.

Related requirements:

Level 2 system requirement follows:

- The 3DoT Spider shall incorporate 3D printed parts for the legs, body, or head. This follows from the level 1 requirement dictating the limit on 3D printing times.

Table of Contents

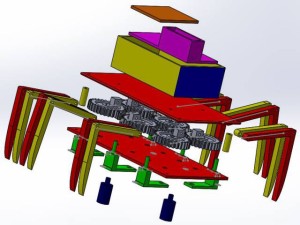

3DoT David Model exploded view and simulation

Exploded View

Simulation

Simulation

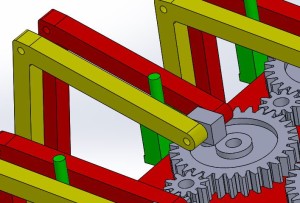

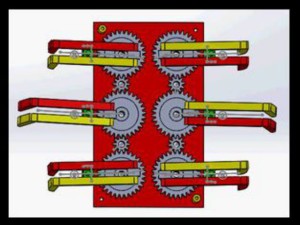

A simulation is shown to clearly define the movement system in different views:

Top view

New Design Parts

Chassis

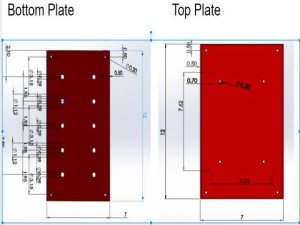

The new design is made in solidworks.These are the top and bottom plates. The top and bottom plate will be assembled together as a chassis for 3Dot David Spider. The dimensions for these plates are 12 centimeters in length and 7 centimeters in width with an extrusion of 0.2 centimeters for each plate. For the bottom plate, holes are 0.39 centimeters. They are made to fit the gears as they rotate on the surface of the plate. Small holes, dimensioned at 0.2 centimeters in diameter, on each plate connect them together. For the top plate, 0.2 centimeters holes are made in the middle to connect the PCB box on top of the plate.

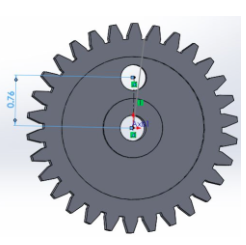

Gears

Gears are bought in Amazon.The large gear has 30 teeth, and measures to be 3 cm. The small gear has 10 teeth, and measures to be 1 cm. 6 large gears and 4 small gears will be used to make the gear train. Calculations are done to obtain the gear ratio.

Refer to Gear train blog post for details (Spring 2016: 3DoT David Gear Train)

Legs

Legs

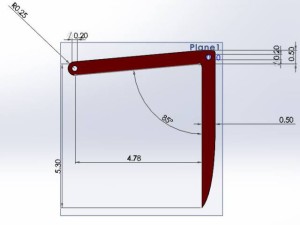

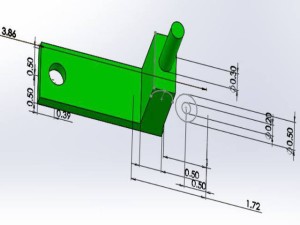

Femur and the tibia are combined as one leg part. The length of the femur is 4.78 centimeters. The length of the tibia is 5.3 centimeters. The hole on the femur is 0.25 centimeters in diameter. The hole will connect the joint as shown on the right. Two legs will have the same dimensions as it connects to joint. The space between the two legs will have 0.5 centimeter cushion.

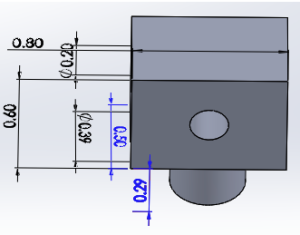

Joint

The joint measures to be 0.8 centimeters in length and 0.6 centimeters in width with an extrusion of 0.5 centimeters. The hole in the box is 0.20 centimeters. The cylinder connected to the box is 0.29 centimeters in length with a diameter of 0.39 centimeters.

Plank, Solidworks modeled gear, and leg studies

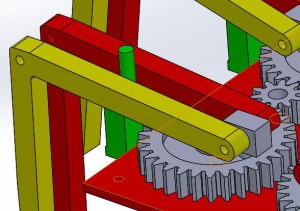

This part is called the plank that will be attached to the bottom of the bottom plate. The reason for the plank is to make the leg, connected to the gear, lift up in an angle as the gear rotates in a full 360 degree rotation. In the 3 centimeter gear, the radius 0.76 centimeters. The gear is modeled to simulate the gear train in Solidworks.

Refer to leg study blog post for calculations ( Spring 2016: 3DoT David Leg Movement Angle Study)

In the middle gear of the gear train, the leg is lifted because of the plank. The lift is about 13.30 degrees according to the leg study. This is the position that it will start for the middle gear.

The position that the corner gear of the gear train will start at is 5 degrees as the leg rests on top of the plank, where the cylinder stops the leg from going anywhere else.

Gear view

A better view is shown from the top as it shows the gear train and the position of all the legs. 12 legs will be used, and 2 legs will act as one part with the same dimensions.

Conclusion:

The previous design was difficult and complex to build similar to the Hexbug Spider. The new design is made to simplify the CAM Movement system of the HexBug Spider, which will be applied to the legs connected to the gears, as the two motors (located on the bottom plate) will rotate both sides of the gears in a full 360 degree rotation. The two motors will attach to the 1 cm small gears.

Corner view

Corner view