Spring 2016 A-TeChToP Manufacturing Design of EDA Watch Bands

Marena William (Manufacturing Engineer)

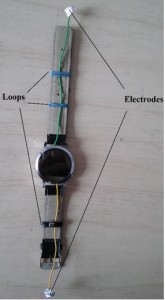

In the past few weeks the housing for the seizure watch was designed and 3D printed as a prototype. The focus currently is on how the electrodes for detecting electrodermal activity will be placed on the wrist and how the electrodes’ wires will be running on the straps of the watch.

A Look at the Backside of the Straps

The housing has two openings, a one on each side (See previous blog post for exact shap of the housing and the location of the holes). As pictured a wire with an electrode at the end will be running on each side of the watch’s strap. The length of the wires is to be adjusted based on the straps’ length which is set to be between 138mm to 161mm fitting children with ages between 8-13 years-old.

Wire Harness

Extra loops will be added to the strap to secure the wires to the backside of the straps which will enable the child to move freely and also make the seizure watch look like any regular watch when it is worn by the child inside a classroom. The wires will also be cut short, only to the length that allow the wires to run from the inside of the housing, where the PCB will be, to the location of the electrodes on the ventral side of the distal forearm.

Securing the Electrodes to the Skin

The electrodes used for the seizure watch are reusable and have non sticky heads. In order to measure the signal from the skin, the electrodes has to be touching the skin with light pressure applied on them. The watch strap will have a variety of holes and a buckle so whenever used the strap will be tied tight to the wrist to ensure that the electrodes are making good contact with the skin.

Attaching the Housing to the Straps

Most of the watches in the market have the straps attached to the case body of the watch (the housing) by a pin. Using a pin allows the customer to change the watch straps to fit different styles and genders and also make it efficient to replace if the straps are worn out.