Spring 2018 3DoT Hexy: Final System Integration and Test

By: Kris Osuna (Electronics and Control Engineer) & Raymundo Lopez-Santiago (Mission, System, and Testing Engineer)

Verified By: Eduardo De La Cruz (Project Manager and Manufacturing Engineer)

Approved By: Miguel Garcia (Quality Assurance)

Table of Contents

Introduction

This blog post covers 3DoT Hexy’s final system and test. Most of the tests were conducted prior do the day of the final (05/15). Tests performed include ultrasonic ranges, light sensor value readings, and arxrobot communication to the pro micro board. Assembly and disassembly were performed on the day of the final.

Update: 05/15/18

The additional test which include the assembly and disassembly were performed. The final time for disassembly was 5 minutes and 10 seconds. The final time for assembly was 7 minutes and 18 seconds. This was timed using a cellphone. Conditions included having the customer present and assembly/disassembly performed by both manufacturing and E&C engineers. Rules and instructions developed for assembly/disassembly can be found below.

Testing

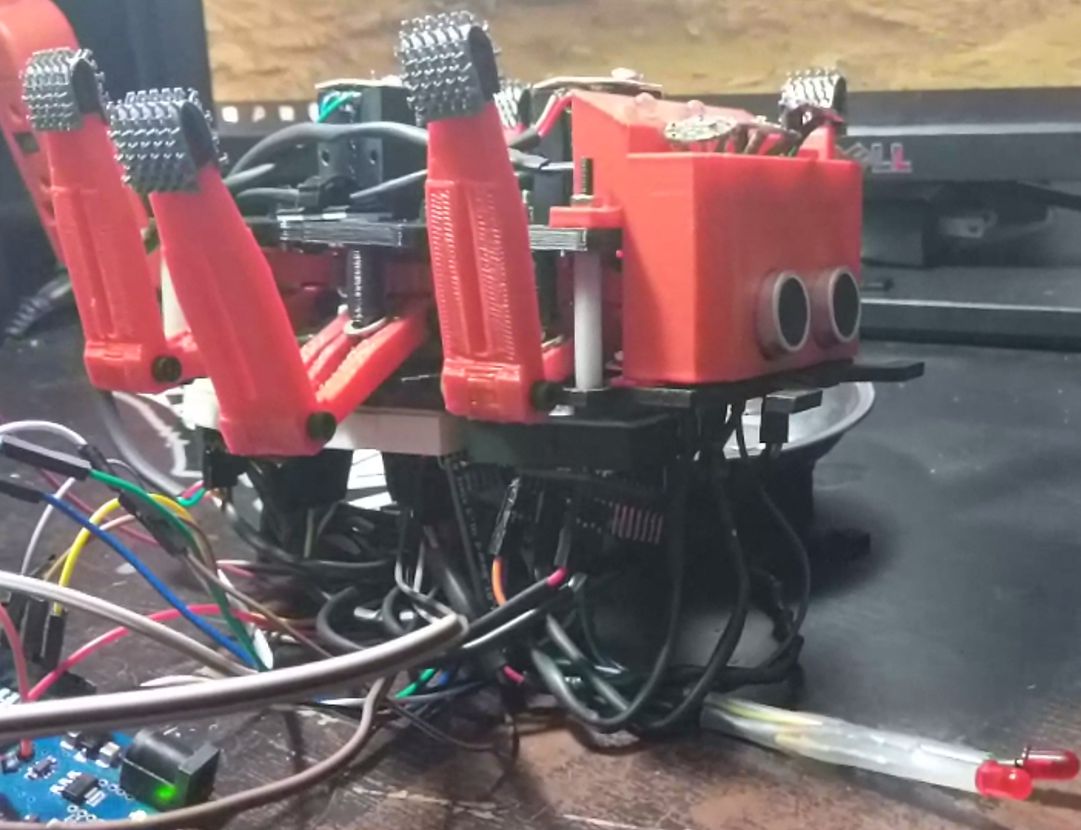

Sensor Testing

Ultrasonic testing (Parallax Ping) was conducted for the requirement of detecting non-navigable obstacles at a distance of no less than 10 cm and no more than 25 cm at a viewing angle (cone) between 30 degrees and 40 degrees facing forward. As seen in Fig. 1, a test was setup to confirm that 3DoT Hexy can detect obstacles within the defined range and conditions. Apart from the robot stopping when an object was detected, two red LEDs were configured to turn on as an additional indication that an obstacle is detected.

Figure 1: Ultrasonic sensor range detection test. Gif can be found below:

Figure 1: Ultrasonic sensor range detection test. Gif can be found below:

Light sensors: Adafruit Flora Si1145

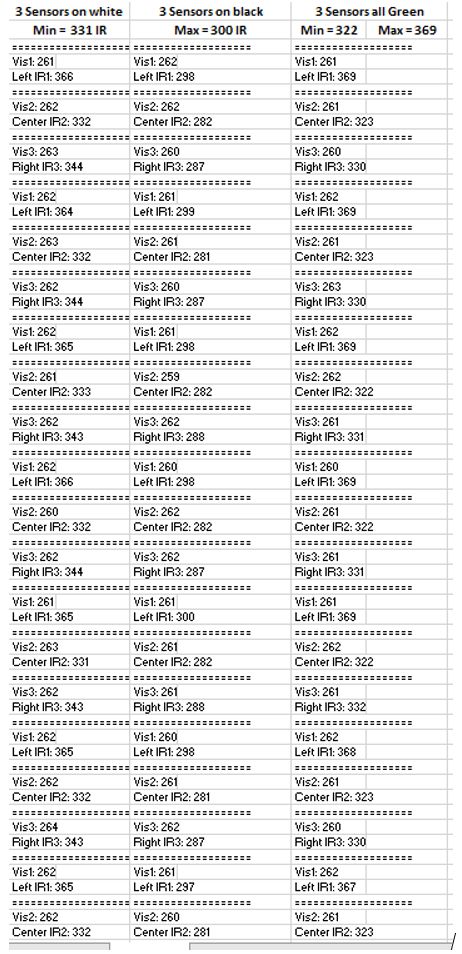

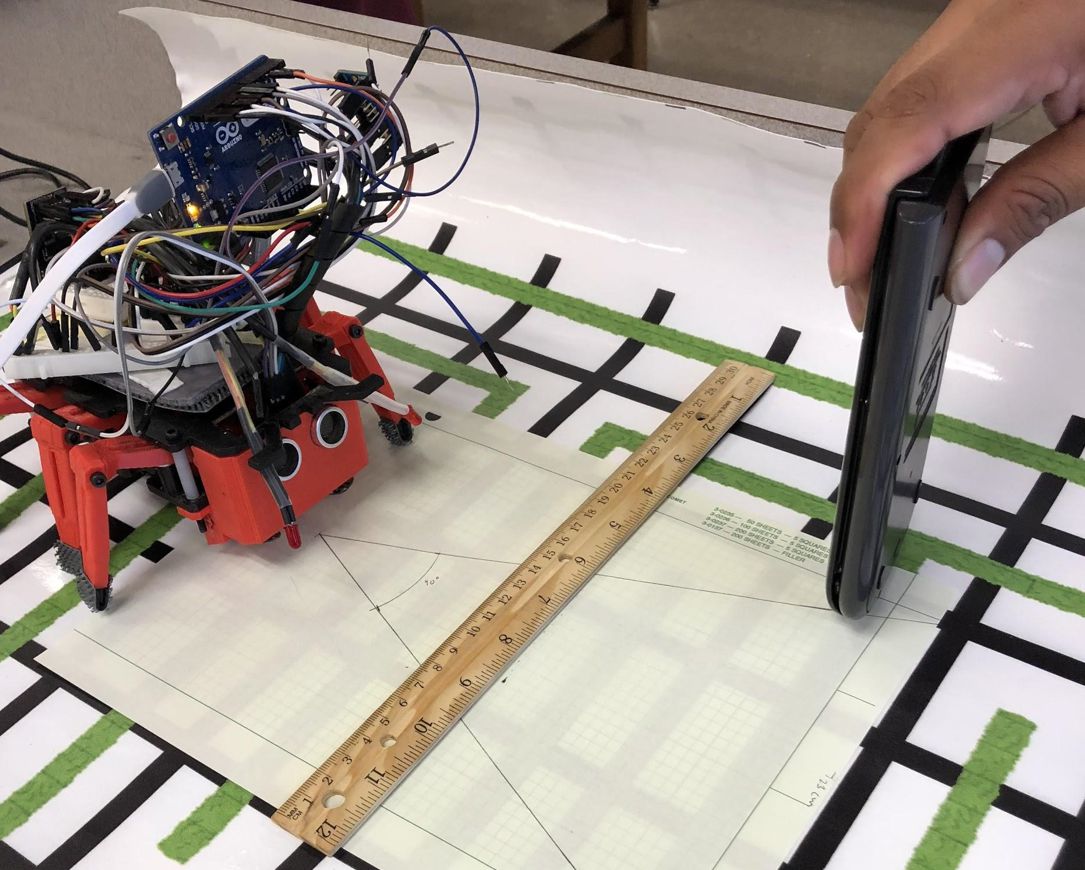

Three light sensors were used for this project. A test was conducted on a maze provided by the customer. A snip of the maze can be seen in Fig. 1. The test included obtaining IR values when the robot is seeing black lines, white lines, and green lines. The distinguishing of color was big enough that line following should be possible. A limit of 310 was placed in the code. The limit will treat whitespace and green lines the same and will not be affected by it. Values on the whitespace gave a minimum of 331. Values on the black lines gave a maximum of 300. Values on the green lines gave a minimum 322 and a maximum 369.

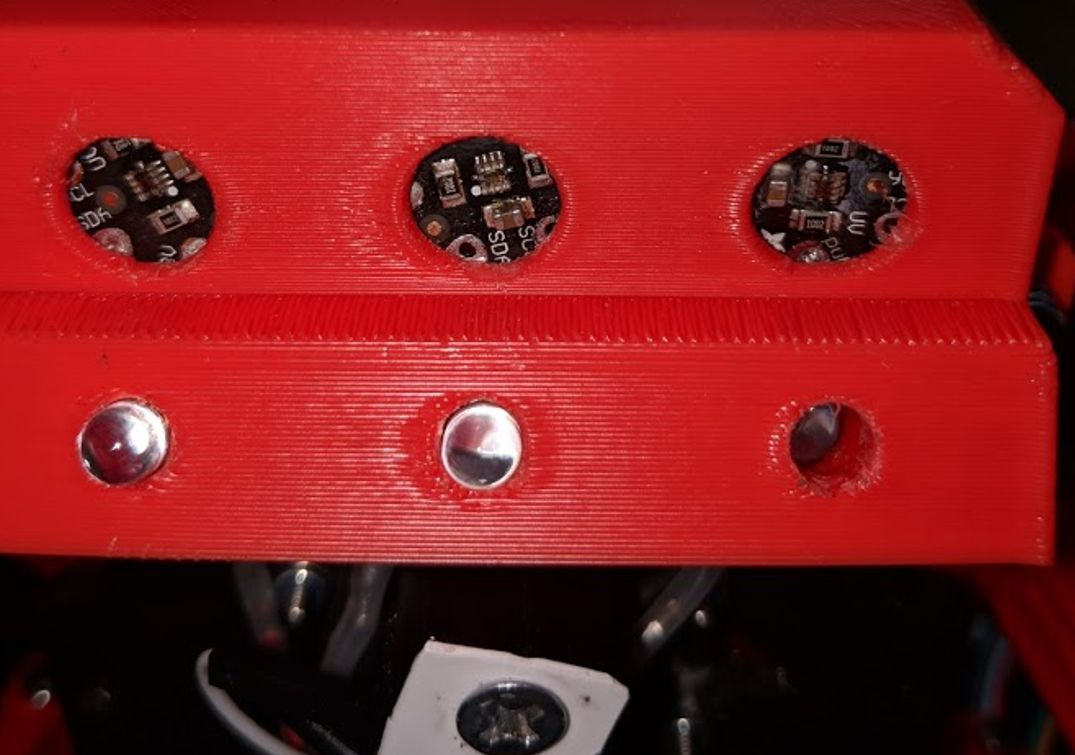

Figure 2: Placement of light sensors

Figure 2: Placement of light sensors

Figure 3: IR and visible spectrum values recorded with the maze values.

Figure 4: Maze value reading set up.

Figure 4: Maze value reading set up.

Arxrobot Communication

As a requirement, the robot shall be controlled remotely via Bluetooth using the Arxrobot phone application. Code tested by the E&C was implemented on the pro micro board. Success criteria were determined to be having the 3DoT Hexy respond to commands from the Arxterra App. I suggest connecting to Bluetooth in an empty space because too many devices try to connect to the app.

Figure 5: A simple LED blink custom command was used to confirm connection to Arxterra App. Gif of the test can be found below

Figure 5: A simple LED blink custom command was used to confirm connection to Arxterra App. Gif of the test can be found below

Conclusion

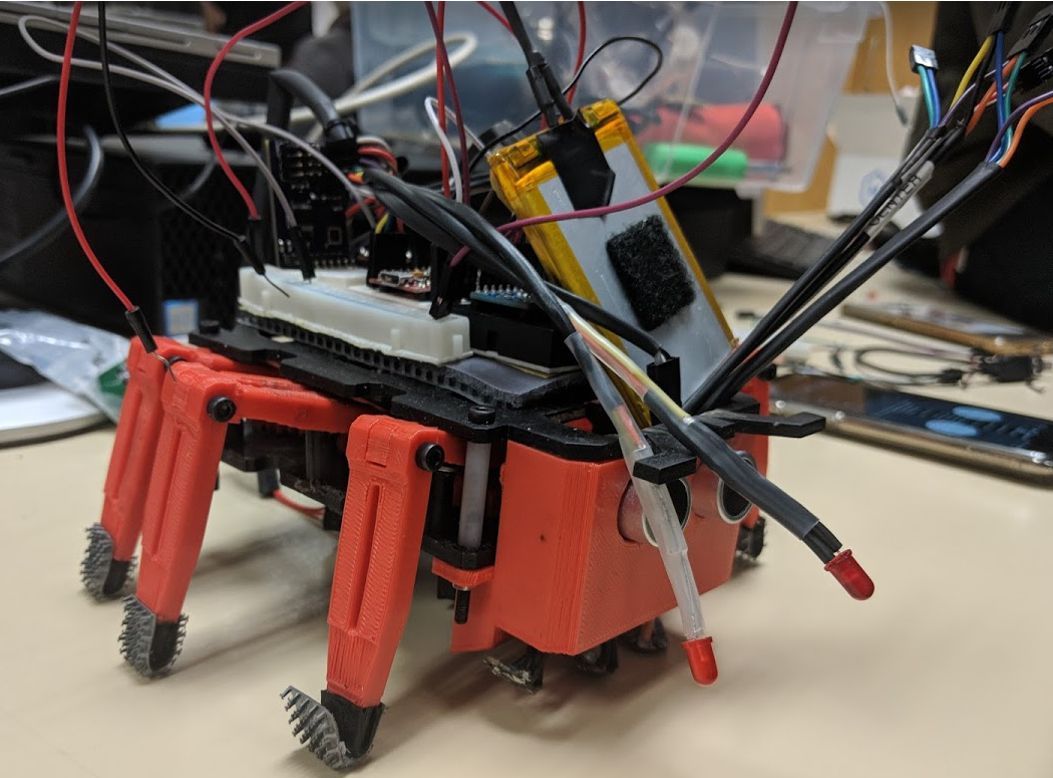

Most of the test conducted were related to the software and sensors used. All mechanical tests were conducted prior to these tests. The bearings added to the gears helped with the ease of movement with only 3.6 V allocated from the battery. Since we did not have the 3DoT board, all testing was done using a Sparkfun 3.3V 8MHz Pro Micro board.

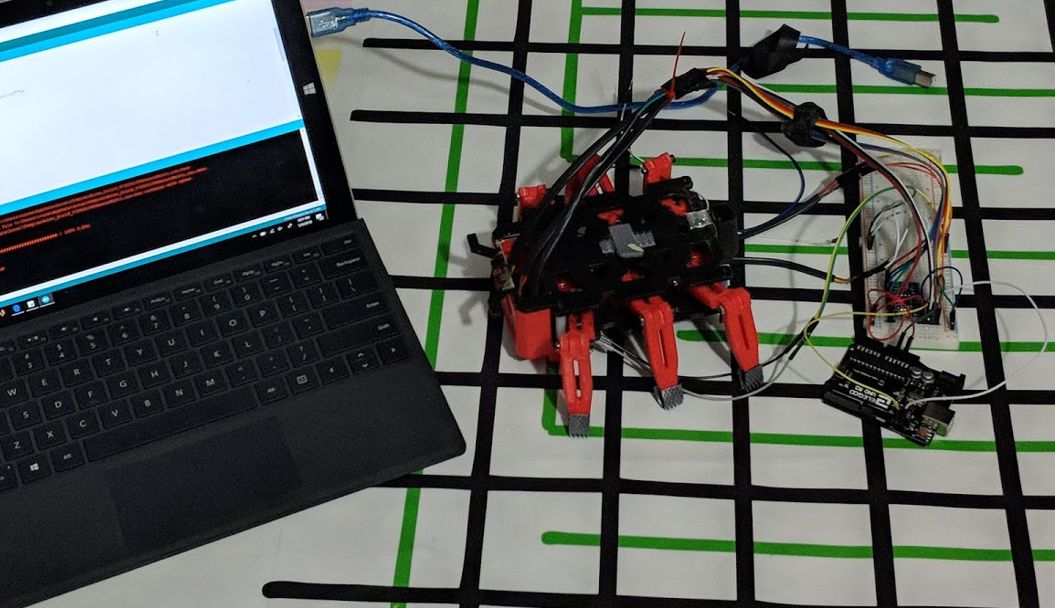

Fig. 6. All components integrated and working together.

Fig. 6. All components integrated and working together.

Fig. 7. Originally Hexy would turn around when an object is detected. Gif of the testing can be found below:

Fig. 7. Originally Hexy would turn around when an object is detected. Gif of the testing can be found below:

Resources

- Ping Code and Wiring

- Si1145 Code and Wiring

- https://www.arxterra.com/wp-content/uploads/2018/05/Assembly2FDisassembly.docx

- https://www.arxterra.com/wp-content/uploads/2018/05/DisguisedBeneficialBrownbear-mobile.zip

- https://www.arxterra.com/wp-content/uploads/2018/05/DelayedBigheartedJaeger-mobile.zip

- https://www.arxterra.com/wp-content/uploads/2018/05/JaggedOblongBighorn-mobile.zip