Spring 2018: BiPed 3D Print Time

Written By: Miguel Gonzalez (Project Manager and Manufacturing)

Approved By: Miguel Garcia (Quality Assurance)

Update: 3D Printing Time Waiver (Approved on 5/01/2018)

Introduction

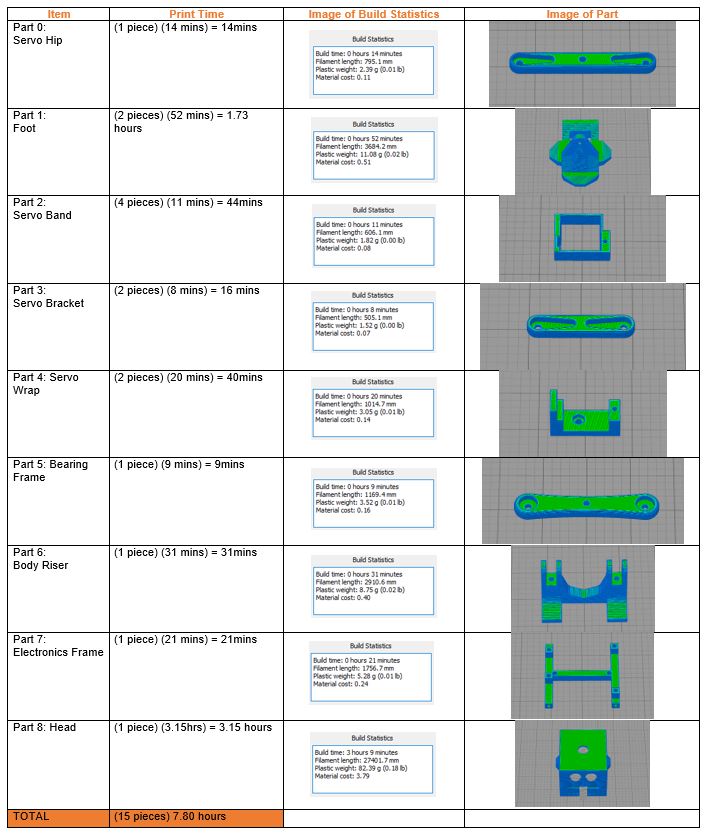

In this blog post, we will cover the overall 3D print time for the complete assembly of the Mirco FOBO. The Micro FOBO’s design is based on the original FOBO which was created by Jonathan Dowdall but utilizes updated and revised components. The design of the components will not be mention in this post but can be found in our Mechanical Design blog post. This post will explore the time it takes to manufacture parts for the Micro FOBO using a 3D printer. To better calculate the amount of time, use for fabrication I have created a table listing all the parts that are needed to assemble our robot and listed the time it takes to make it. Micro FOBO uses a total of fifteen 3D printed pieces which takes seven hours and forty-eight minutes. It is important to note that our current printing time violates our customer’s program requirement of keeping the printing time under 6 hours total. Only the head of FOBO exceeds the 2-hour limit of 3D printing requirement per part. Due to this violation, we have decided to appeal this requirement with a waiver document. By getting the approval of the customer through this appeal we won’t need to make any changes to our design or 3D printing process.

Related Requirements

Level 1 Requirements:

L1-8: Micro FOBO’s part components will be 3D printed using the material carbon fiber PLA.

L1-9: Micro FOBO will not exceed a print time of 7.80 hours. Upon approval of the waiver.

Level 2 Requirements:

L2-2: Micro FOBO dimensions will need to be small enough to fit in a 4in by 4in box for maze purposes.

L2-15: Micro FOBO shall weigh no more than the allocated mass of 460g.

Table Data:

The table above shows Micro FOBO’s parts listed with their own “Build Statistics” which is information about the part’s printing time, weight, and cost of materials. This information was gathered through the slicing software, Simplify3D. All parts were listed to have a layer height of 0.20mm and 25% infill when producing the printing time information.

Final Remarks

It is important to note that the printing time shown above has been completely processed via slicing software but has been verified to be correct when printing the first full prototype. All 3D printing is done through my own 3D printer but the material (Carbon Fiber PLA) bought will be processed for reimbursement. As mentioned before, we currently exceed the amount of time allocated by the customer for printing time. The main reason we cross the six-hour mark is due to the head of FOBO requiring large amounts of support material and thus requiring more time to print out. We hope that the customer accepts our printing time waiver to allow us to keep the same head design and printing process.