Spring 2018: BiPed (Micro FOBO) System Block Diagram

By: Jorge Hernandez (Electronics & Control Engineer)

Verified By: Miguel Gonzalez (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

System Block Diagram

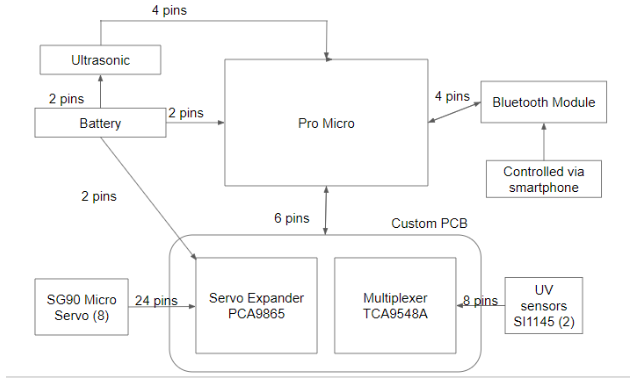

New and improved System Block Diagram for Micro Fobo, which shows in a general diagram, how many pins will be needed for each component and how they connect to each other. As seen, we are using a total of 5 sensors, a custom PCB, Bluetooth module, external battery and of course a Pro Micro. This helps a lot for our E&C engineer when it comes to PCB designing as they need to plan accordingly.

The sensors subsystem (custom PCB) will be in charge of telling Micro FOBO’s next action. When the IR sensor on the UV breakout board sense a change in IR reading, this will alert the Pro Micro which ultimately leads to the Actuators subsystem (Micro Servos) to adapt accordingly based on our code. The same process will occur when the Ultrasonic sensor senses an object or a wall ahead of Micro Fobo. Bluetooth is considered a sensor because it collects inputs from a source, in this case, an Android phone then sends that data to the Pro Micro thus telling Micro FOBO what to do based on our code. The communication subsystem (Bluetooth module) is connected to the Pro Micro because through Bluetooth the Arduino will obtain information on the action it will take. The Power subsystem consists of the battery which has been tested for our overall system and a regulator to ensure the safety of the system and the user(s). Our Actuator subsystem is our output, Micro FOBO’s desired movement, based on our sensors and code